The twin-wall corrugated pipe is a pipe made of polyethylene or polypropylene. It can be used as a cable conduit or for the passage of non-pressurised sewerage distribution networks. In both cases, we are talking about an underground corrugated pipe installed outside the buildings.

There is only one way to produce corrugated pipes, the only difference to be found in the various manufacturers is the method of obtaining ring stiffness. This can be achieved by changing the height and/or spacing of the corrugation or by changing the thickness of the rib.

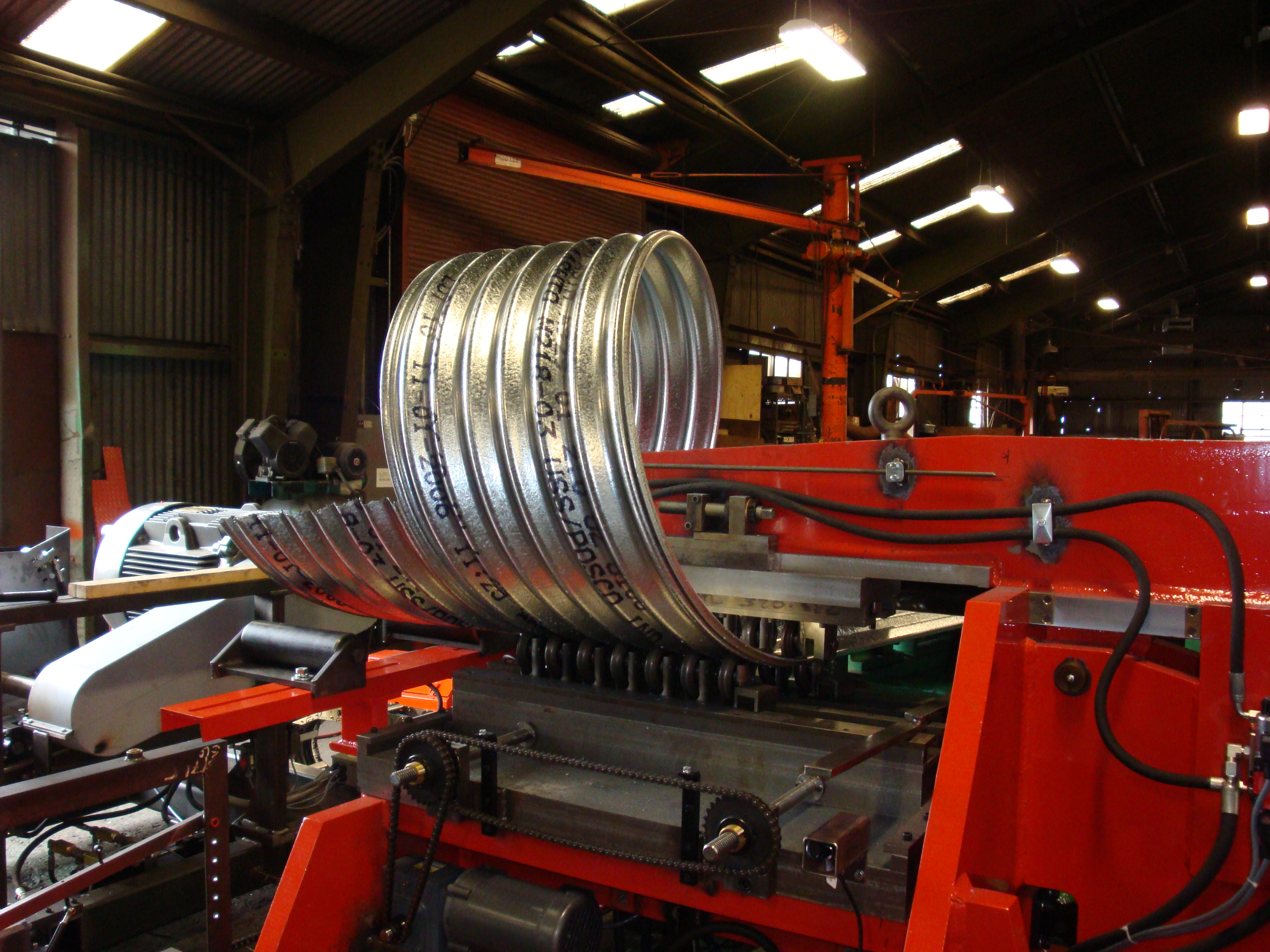

The production technology is called co-extrusion because the system consists of an extrusion head that emits material from two concentric dies. The outer corrugation is formed by a series of moving dies with a caterpillar-like movement.

Let’s now take a look at all the steps in the manufacturing process of twin-wall corrugated pipes:

- the grains of polyethylene (or polypropylene) are conveyed from the storage bins to the hoppers placed on the extruders. The extrusion capacity of the two extruders is different depending on the amount of material used for the two walls; the inner wall corresponds approximately to 2/5 of the pipe overall mass;

- the external die produces a “pipe” which is pushed and sucked by the dies so that the fluid material rests on the internal wall of the die and takes the shape of the corrugation;

- the internal die forms the internal wall of the pipe by extruding a second pipe whose circular shape and inside diameter are controlled by the cooling mandrel;

- near the cooling mandrel, the corrugation, which is already formed but still at high temperature, merges with the internal layer. The extrusion speed and the die feed speed are calibrated in order to ensure a homogeneous structure with optimal geometrical parameters; the adjusting parameters are controlled by a software while vacuum and air are controlled by special valves;

- the pipe resulting from the co-extrusion process is first cooled by water cooled dies that maintain a steady temperature. The pipe is later water cooled and cut at the desired length at the section between the ribs.

This results in an underground corrugated pipe with a smooth inner wall and a corrugated outer wall.