-

- Coiling: A coiling machine pulls a straight wire through rollers and guide sets to shape it into a helical coil.

- Forming: A forming machine uses tooling slides to cold-work the wire into a coil.

- Grinding: The ends of compression springs are ground flat so they can stand upright.

- Shot peening: A machine strengthens the steel by adding compressive force to the outside of the spring. This helps prevent cracking and corrosion.

- Coating: The spring is coated with liquid rubber or plated with a metal like zinc or chromium. Plating can improve the spring’s strength, corrosion resistance, and physical properties.

- Coiling: A coiling machine pulls a straight wire through rollers and guide sets to shape it into a helical coil.

- Presetting: The spring is compressed to its solid height or a given load point to remove “the set”.

- Tempering: The spring is heated to 920°C, cooled in quenching oil, and then heated again to 450°C. This process establishes the spring’s ductility.

- Springs come in a wide variety of sizes and configurations depending on their desired use. Some of the types of springs include leaf springs, Belleville washer springs, clock springs, constant force springs, and helical coil springs. MW Components specializes in manufacturing helical coil springs from high-quality U.S. steels.

The most common types of coil springs are compression springs. These springs store energy which can be measured through an increase in the load or force required to compress them. Other types of coil springs include torsion springs, which increase in load with radial loading, and extension springs, which increase in load as the spring length is increased.

The Difference Between Hot Wound & Cold Wound Springs

-

Coil springs can be manufactured through either cold wound or hot wound coiling processes.

Coil springs can be manufactured through either cold wound or hot wound coiling processes.Hot Wound Springs

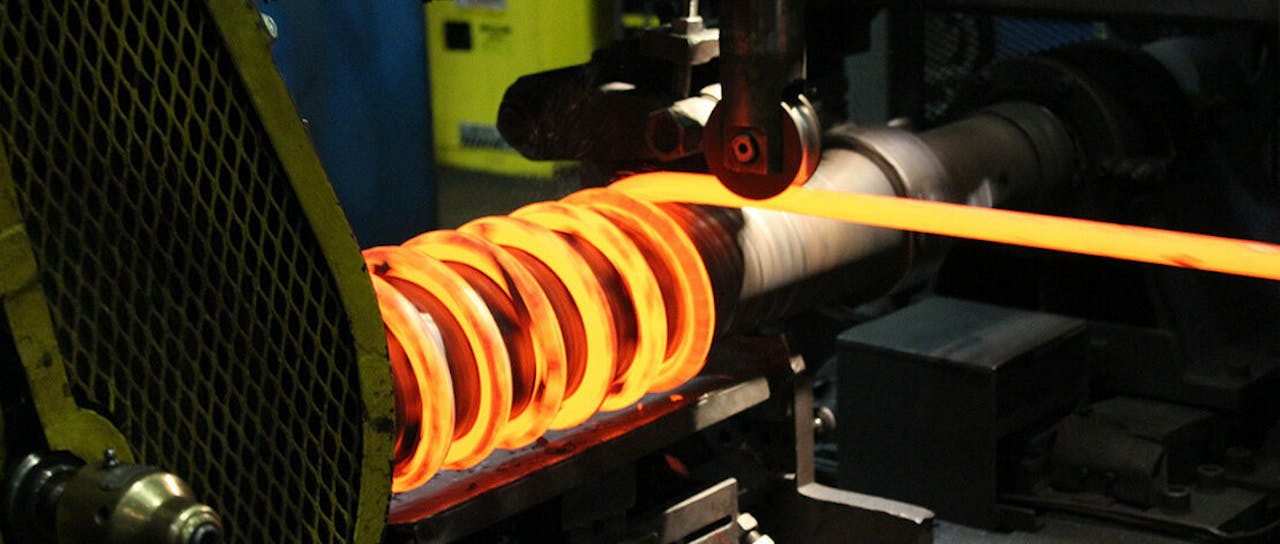

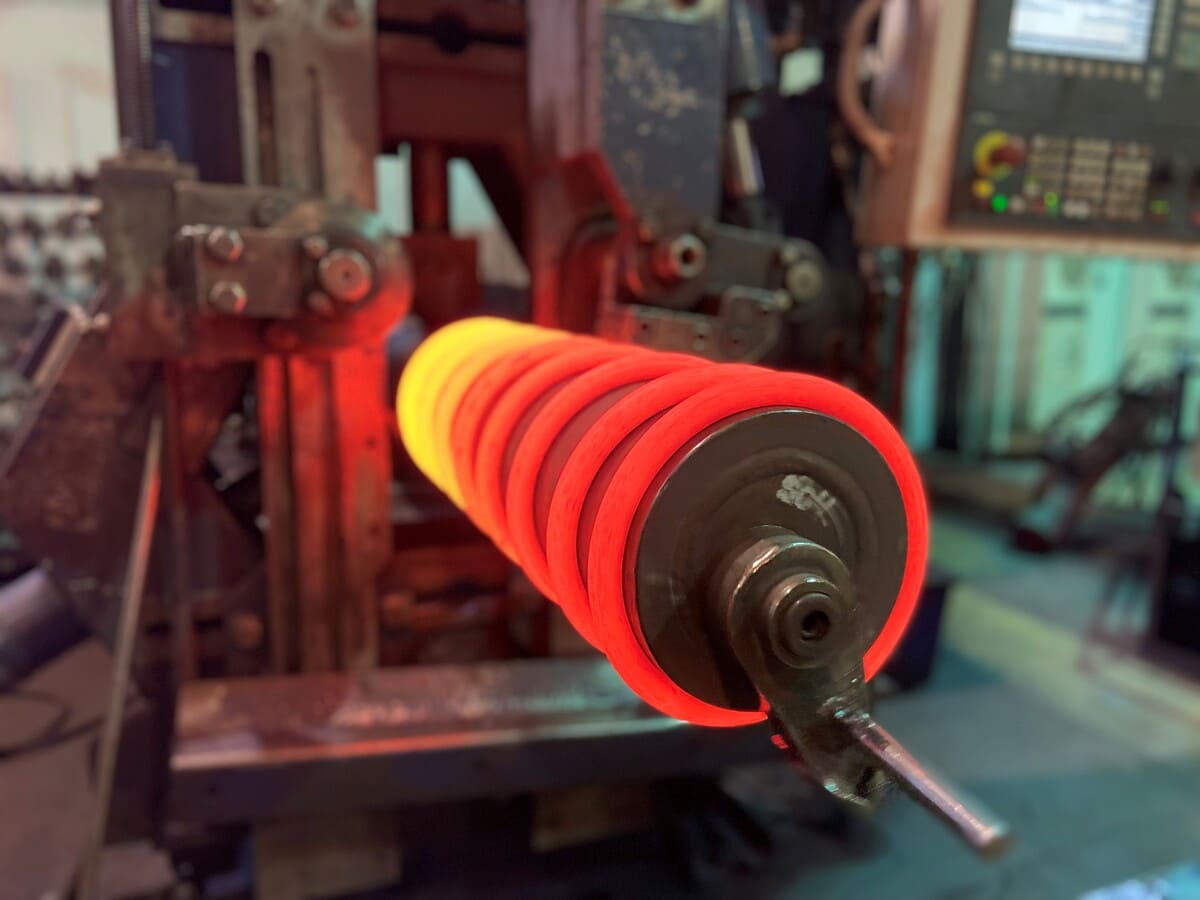

In hot wound coiling, the material is heated to austenitic temperatures of over 1550F, formed on the coiler, and then quenched in oil to form martensite. Next, the springs are tempered to change the microstructure to a tempered martensite which provides strength to achieve the desired spring performance and ductility to withstand the operation. Hot wound coiling is usually for larger bars sizes over 0.500” (12 mm). MW’s Greer location can coil bars up to 3.00” (75 mm) in 5160H, 51B60H and 4161H material. Additional materials, such as Inconel and Stainless Steel, can be coiled through hot winding, but these materials are not included in our standard raw material inventory.

MW Components utilizes a continuous heat-treating process to manufacture hot coiled springs. Every bar and every spring in a lot goes through the entire length of the furnaces. This means that each bar, and therefore each spring, gets a consistent heat treatment and is not dependent on its position in the furnace. This is a distinct advantage over batch processes where each spring receives a different heat treatment depending on where and when the material is placed in the furnace.

Cold Wound Springs

Cold coiled springs are made from fully heat-treated material and then stress relieved to remove the stresses induced during the coiling process. MW Components – Greer: Springs can coil up to 0.625” (15.8 mm) in Chrome Silicon and Oil Tempered Wire. MW can also coil high tensile Chrome Silicon to 0.437” (11 mm) and in 2019 we will extend our range for high tensile Chrome Silicon over 0.625” (15.8 mm).